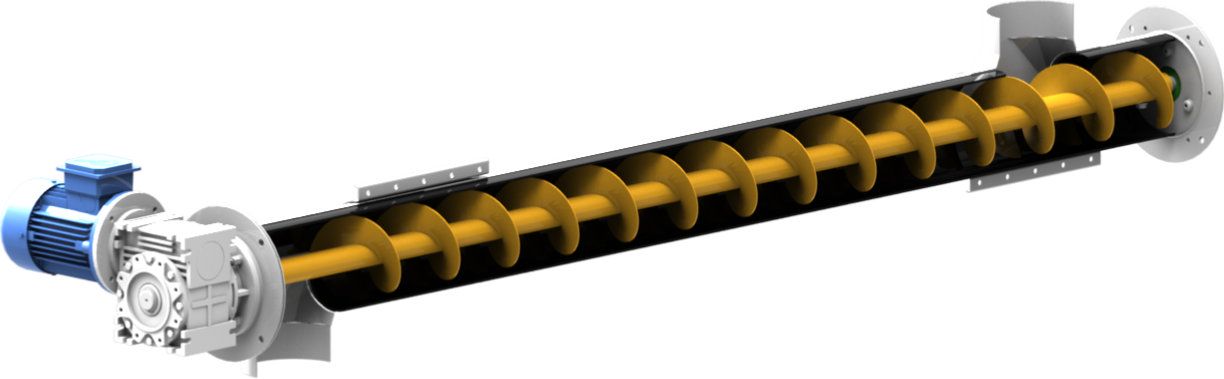

PSR tubular screw conveyor (screw) - horizontal transport device

We manufacture PSR tubular screw conveyors with a capacity of 20 to 40 t / hScrew conveyors

PSR conveyors manufactured by AG-PROJEKT are designed for horizontal transport of loose materials such as:

- cereal grains

- legumes

- oilseeds

- granules

- corn

- pellets

PSR - 20 [t / h] (PSR200) and 40 [t / h] (PSR 200) capacities are the most often required and occurring when transferring material over short distances. The screw-tube (screw) conveyors of the PSR200 / 20 and PSR200 / 40 series intended for grain transport have a modular structure that allows easy configuration of the device depending on the user's needs. The PSR screw-pipe conveyors include pipes with at least one discharge (material unloading) and charging (material loading) opening. The charge and discharge can be adapted to the shape of a square, rectangular or round, for this purpose should be consulted with the sales department . Our offer includes devices with a length of 2m to 6m.

The work of the conveyor can be done by switching on manual or automatic control adapted to the existing system of the customer

Recommended horizontal work position. It is possible to mount our devices at an angle ranging from 0st to 30st. Depending on the angle, the nominal capacity of the device decreases (when using the same drive). The innovative solution is lining the pipe from the inside with PE-UHMW material with a reduced coefficient of friction.

This solution has the following advantages:

- makes it easier to move the transported material,

- significantly reduces the consumption of conveyor components having direct contact with the transported material,

- reduces the power demand for conveyor drive,

- reduces damage to transported grains, reduces noise resulting from grain travel.

Model PSR

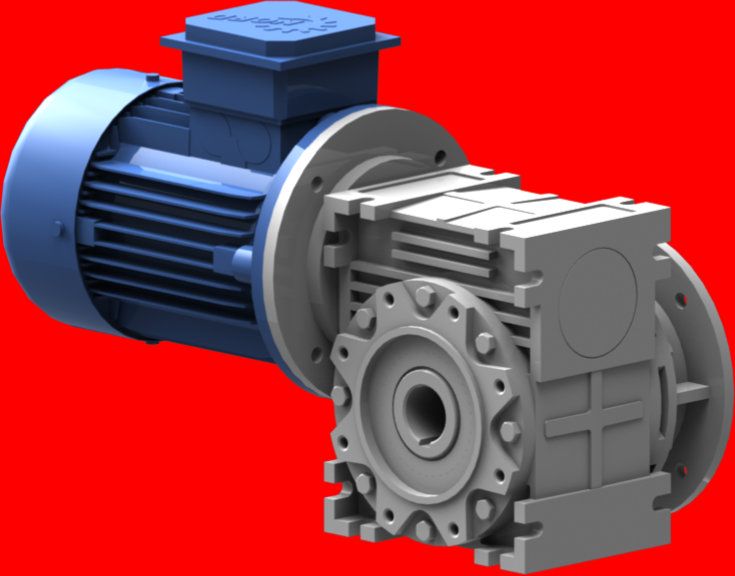

Geared Motors

Main drive

The appropriate gearmotor model is selected for the ordered PSK model

Geared motor

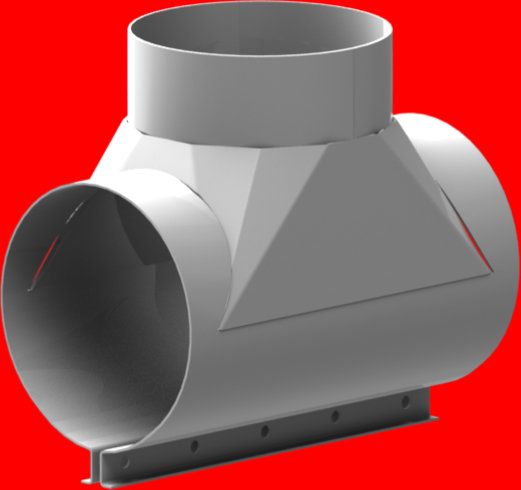

Discharge element

Element responsible for spilling material from the PSK conveyor.

Depending on the model and its parameters, the discharge element may have a different diameter adapted to technological lines.

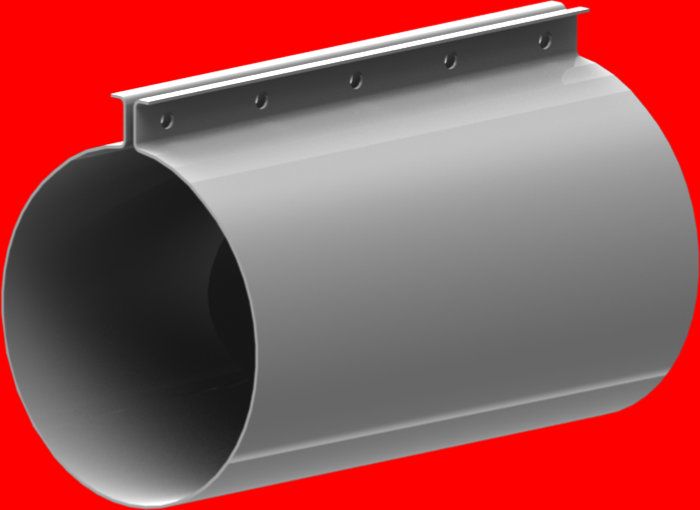

Pipe connector

An element connecting pipes

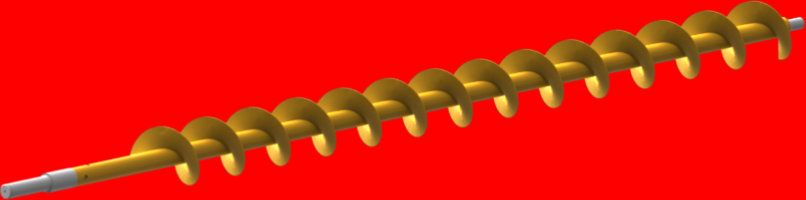

Scroll module

The team with the worm shafts.

The shafts enter the bearing openings and the gear motor drive.

PE-UHMW

Hard-wearing PE-UHMW

conveyor inlet

The PSR inlet can be mounted along the pipe anywhere. Depending on the model and its parameters, the charging element may have a different diameter adapted to technological lines.

It is possible to mount several inlets

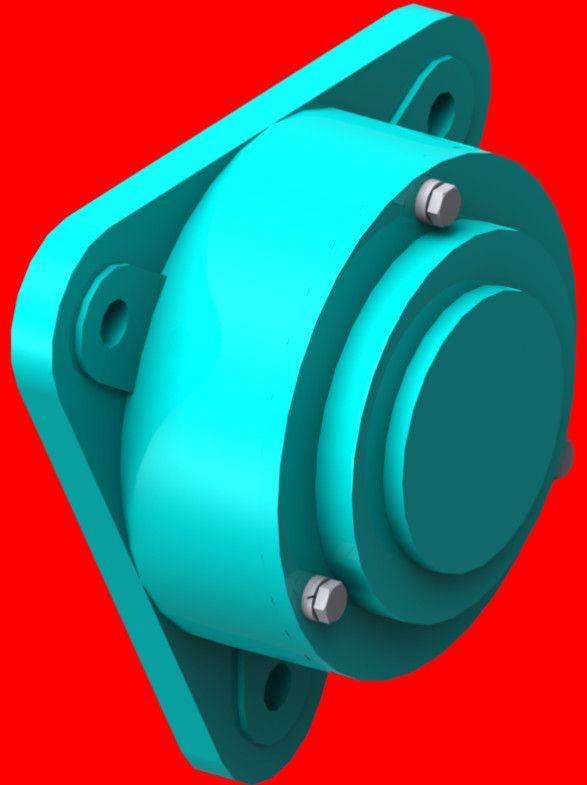

Rear end bearing

End piece closing the PSR drive system (bearing)

Our devices have all the necessary certificates allowing the product to work in accordance with the standards.

We encourage you to contact us by phone or e-mail regarding the PSR conveyors. We provide advice in the selection and configuration of an assortment. Our experts will explain all technical matters related to products from the AG-PROJEKT company.

Przenośnik Ślimakowy

Technical data:

| Parameter | Unit | PSR160 | PSR200 |

| Engine rated power | kW | 2,2-4,0* | 2,2-7,0* |

| Screw rotation speed | obr/min | 114-143* | 280-373* |

| Pipe diameter Ø | mm | 200 | 200 |

| The diameter of the worm Ø jump | mm | 160/160 | 160/160 |

| Nominal capacity | ton/godz. | 20* | 40* |

Equipment efficiency given for wheat grain with a moisture content of 16% and a density of 0.75 g / cm3. We have an ISO9001 quality management system. We reserve the right to make technical changes. We have an ISO9001 quality management system. We reserve the right to make technical changes.

DOWNLOAD:

Welcome to the gallery of objects